- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Author: Site Editor Publish Time: 2025-10-28 Origin: Site

If you've ever wondered why some cars feel so responsive yet stay cool under pressure, it often comes down to the materials inside the engine. Modern engines face two big demands — being light enough to boost performance and tough enough to handle extreme heat. Finding the right balance between the two is what makes an engine both powerful and reliable.

Let's explore how different materials influence engine performance, what trade-offs exist, and why this balance matters for anyone who loves cars.

Lightweight engines allow cars to accelerate faster, handle better, and burn less fuel. But there's a catch — the lighter the material, the less heat it can usually tolerate. Since engine temperatures can easily exceed 800°C, parts need to withstand constant heat without losing strength.

Here's a quick look at how weight and heat resistance affect engine behavior:

| Property | How It Affects Driving | Typical Goal |

| Weight | Improves acceleration, reduces fuel consumption, and enhances balance | About 20–30% lighter than traditional cast iron |

| Heat Resistance | Keeps the engine stable during long drives and prevents overheating | Must handle 600–900°C safely |

| Thermal Conductivity | Helps heat escape quickly for smoother operation | Over 100 W/m·K for critical parts like pistons |

Simply put, a good engine material should stay light under load and strong under heat.

Different car models use different materials depending on how they're driven. Sports cars, for example, prioritize speed and acceleration, while daily drivers focus more on cost and durability. Here's how some common materials stack up:

| Material | Density (g/cm³) | Max Temp (°C) | Strength-to-Weight | Common Use |

| Aluminum Alloys | 2.7 | 350-400 | Moderate | Pistons, cylinder heads |

Magnesium Alloys | 1.8 | 250-300 | High | Engine covers, supports |

| Titanium Alloys | 4.5 | 600-650 | Very high | Valves, connecting rods |

Nickel Alloys (Inconel) | 8.4 | 900-1000 | Excellent | Turbochargers, exhaust parts |

| Carbon Fiber Composites | 1.6 | Up to 200 (with coatings) | High | Air intake covers, housings |

Each material offers a unique balance. Aluminum is affordable and light but doesn't love extreme heat. Titanium is strong and heat-resistant but costly. And Inconel? It can take incredible temperatures — though at the expense of added weight and budget.

There's no perfect material that's both feather-light and heat-proof. The key lies in choosing where to prioritize each quality.

Aluminum keeps engines light and responsive — ideal for most street cars. It's common in pistons and cylinder heads but tends to weaken at high temperatures. That's why many automakers add coatings or reinforcement to help it last longer.

Titanium shines in high-performance vehicles. It's stronger than aluminum and can handle much higher heat, making it perfect for moving parts like valves and rods. The only downside? It's expensive and harder to machine, which limits its use to premium or racing engines.

Inconel and similar alloys are designed for the hottest parts of an engine — especially turbochargers and exhaust valves. They're heavy and pricey but nearly unbeatable for extreme durability.

Instead of relying on one "super material", modern engines use hybrid approaches to get the best of both worlds. You might see:

Ceramic coatings on pistons to reflect heat away.

Carbon fiber housings in lower-heat zones to reduce weight.

Aluminum matrix composites with ceramic reinforcements for added strength.

By combining materials intelligently, designers make engines that are lighter, cooler, and longer-lasting — something every driver benefits from.

When you choose a performance vehicle, you're not just buying horsepower — you're buying material science in motion. Lightweight components give sharper throttle response and better handling. Heat-resistant materials keep your car reliable during hard driving or hot weather.

If you're modifying or upgrading your vehicle, understanding these materials helps you pick parts that match your driving style — whether you're chasing lap times or just smoother, more efficient rides.

Balancing lightweight design and heat resistance isn't just an engineering problem — it's what separates a good engine from a great one. Every gram saved and every degree resisted adds up to better performance, fuel efficiency, and reliability.

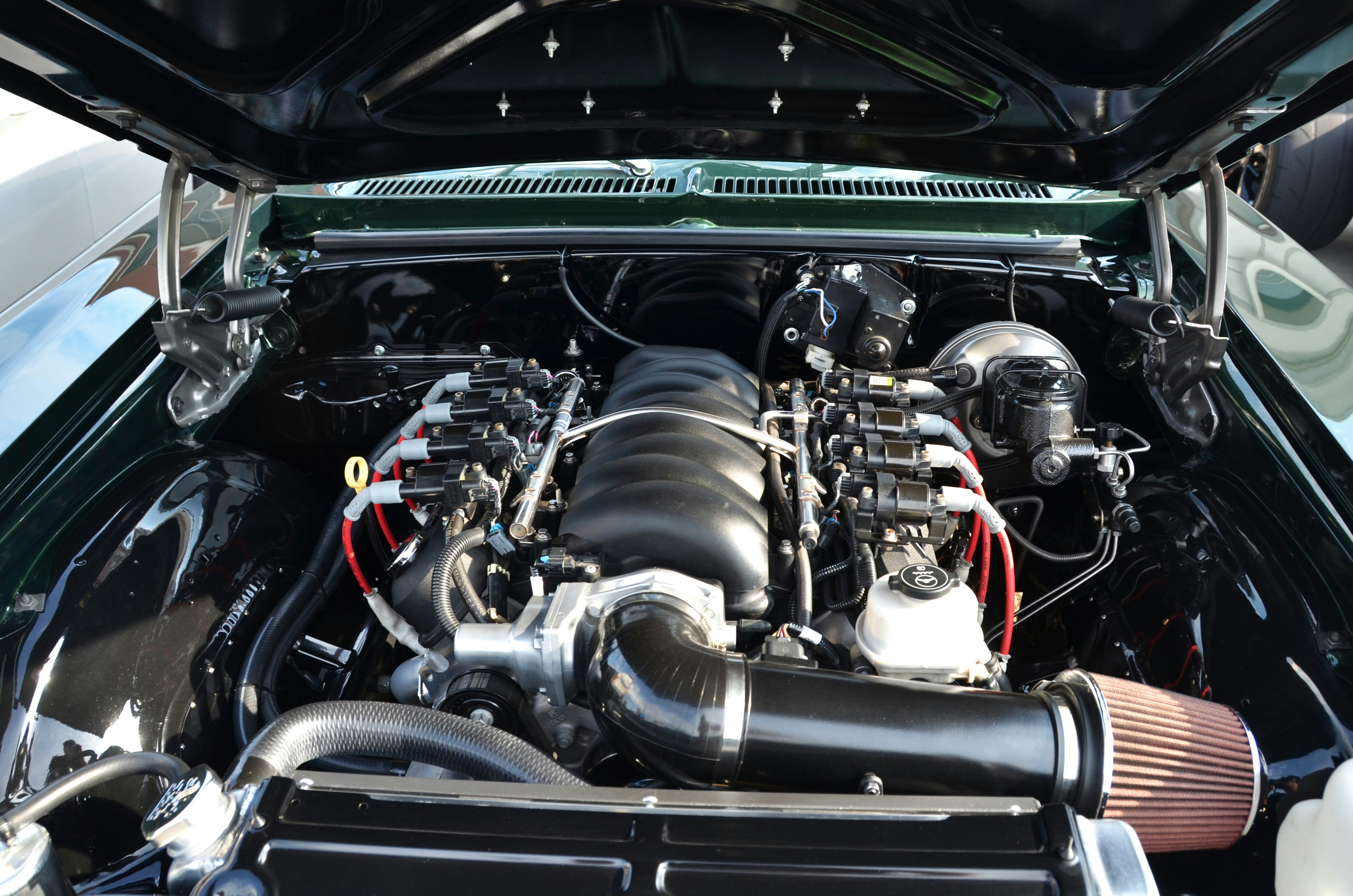

So next time you pop the hood or read a spec sheet, take a moment to appreciate how much thought goes into those shiny metal parts — because behind every powerful engine lies a perfect balance of science, heat, and speed.

The Transition Path from Traditional Fuel Engines to Hybrid Power System

Why Is the Tightening Order of Engine Cylinder Head Bolts So Important?

How to Balance Lightweight and Heat Resistance When Selecting Materials for High-Performance Engines

The Manufacturing Process of Engine Sensors: From Chip to Finished Product

A Comparison of Mercedes-Benz and BMW Engine Crankshaft Position Sensor Technology

BMW Engine Structural Characteristics And Common Parts Failure Analysis

Detailed Explanation of Key Sensors in BYD Hybrid Engine System

BMW N Series Engine Common Spare Parts Wholesale Recommendations And Application Scenario Analysis

Five key sensors commonly used in Audi engines and their functions

Audi Engine Technical Analysis and Common Parts Replacement Guide

| Hotline free 24/7 86-15279198783 |